Del Mar Photonics - MCP products

Microchannel Plates

MCP is a specially fabricated plate that amplifies electron signal similar to secondary electron multiplier (SEM). Unlike SEM, MCP has several million independent channels and each channel works as independent electron multiplier. In other words, one can imagine MCP as an assembly of millions miniature SEMs. MCP consists of a two-dimensional periodic array of very-small diameter glass capillaries (channels) fused together and sliced in a thin plate. A single incident particle (ion, electron, photon etc.) enters a channel and emits an electron from the channel wall. Secondary electrons are accelerated by an electric field developed by a voltage applied across the both ends of the MCP. They travel along their parabolic trajectories until they in turn strike the channel surface, thus producing more secondary electrons. This process is repeated many times along the channel; as a result, this cascade process yields a cloud of several thousand electrons, which emerge from the rear of the plate. If two or more MCPs are operated in series, a single input event will generate a pulse of 108 or more electrons at the output.

Since the individual channels confine the pulse, the spatial pattern of electron pulses at the rear of the plate preserve the pattern (image) particles incident on the front surface. The output signals are typically collected in any of several ways, including metal or multimetal anodes, resistive anode (one- or two- dimensional), wedge and strip anode, Delay-Line Readout or on a phosphor screen deposited on a fiberoptic or other substrate.

Microchannel Plates have a combination of unique properties like high gain, high spatial resolution and high temporal resolution. They can be used in a large variety of applications including, imaging spectroscopy, electron spectroscopy and microscopy, mass spectrometry, astronomy, molecular and atomic collision studies, cluster physics etc. Most of these applications require only some of MCP properties, for example Time-of-Flight Mass Spectrometry require high temporal resolution of MCPs, imaging of single atoms in field ion microscopes or X-ray imaging of the Sun require mainly spatial resolution. Particle analyzers may be produced by using a MCP detector at the output of a electrostatic and/or magnetic dispersion system. Very high sensitivity optical, UV and EUV and X-ray spectrometers can also be produced with appropriate filtering and dispersive elements. The same microchannel plate technology is used to make visible light image intensifiers for night vision goggles and binoculars.

Detectors based on Microchannel Plates have variety of designs depending on the type of particles detected, throughput (counts/second), time and position resolution, imaging area, linearity and sensitivity, signal to noise ratio and other requirements. It's a challenge to detector developer to optimize detector design for particular application.

In general, each detector that uses MCPs consists of three parts:

1) A Converter - a mechanism to convert initial particles in photons or electrons,

2) An Assembly of MCPs - a mechanism to amplify initial single electron or photon event into electron pulse and

3) A Readout Device - a mechanism to detect the electron avalanche.

Del Mar Photonics supply Microchannel Plates, MCP assemblies as well as custom-made systems including mounting and readout device (s). This brochure describes Microchannel Plates, Open Microchannel Plates Detectors with Metal Anode and Open Imaging Detectors (Image Intensifiers).

Microchannel Plates

|

|

The microchannel plate is an open multiplier intended for registration of particles and radiations. MCPs represent 0.4-3.0 mm thick plates of round or rectangular shape. They have a honeycomb structure and contain in one square centimeter up to one million of separate channels of 5-15 m m diameter. In addition to design simplicity, small dimensions and absence of external voltage divider, MCPs feature high time and spatial resolution capability. |

Construction and Operation

A Microchannel Plate begins as a glass tube fitted with a solid, acid-etchable core and drawn via fiberoptic techniques to form single fibers. A number of these fibers are then stacked in a hexagonal array; the entire assembly is drawn again to form multi-fibers. The multi-fibers are then stacked together and fused at high temperature to form a boule.

The boule is sliced on a wafer saw to the required bias angle, edged to size, and then ground and polished to an optical finish. The individual slices are chemically processed to remove the solid core material, leaving a "honeycomb" structure of millions of tiny holes.

Through subsequent processing, this glass wafer is given its conductive and secondary emissive properties. Finally, a thin metal electrode (usually Inconel, Nichrome or chromium) is vacuum-deposited on both input and output surfaces of the wafer to electrically connect all the channels in parallel.

|

Honeycomb structure of Microchannel Plates. For additional images of Microchannel Plate surface at different spatial resolution click here. |

For normal operation, a bias of about 1000 Volts is applied across the microchannel plate, with the output at its most positive potential. The bias current flowing through the plate resistance is what supplies the electrons necessary to continue the secondary emission process. Electron multiplying process was described above. Below we consider most important properties of Microchannel Plates.

Shape and Size

Microchannel plate arrays may be fabricated in a wide variety of formats. The MCPs may range in size from 6mm to 100mm or larger, and they may be circular, rectangular, or virtually any other shape as required by the application or instrument geometry. In addition, a cylindrical or spherical radius of curvature may be provided to conform to the focal plane of an instrument.

A border glass area surrounds an effective area of MCP where channels are arrayed. Table below shows dimensions of standard MCPs, supplied by Del Mar Ventures.

| MCP type (part #) |

25-10E* |

33-10E |

34-10 |

46-12 |

56-15 |

43*63 |

70*90 |

| Diameter, mm

Length, mm Width, mm |

24.8 |

32.8 |

34 |

46 |

56 |

63 43 |

90 70 |

| Effective Diameter, mm |

18 |

25 |

30 |

40 |

50 |

38*58 |

65*85 |

| Channel Diameter, m m |

10 |

10 |

10 |

12 |

15 |

15 |

15 |

MCP Thickness and Channel Diameter

The length of the channel of a MCP is virtually its thickness. The ratio of the channel length (L) to the channel diameter (d) L/d, as well as the inherent secondary emission factor of the channel wall material determines the gain of the MCP. The standard MCPs are fabricated with a L/d ratio about 40 to 80.

Channel Bias Angle

The channel bias angle is an angle formed by the channel axis and the vertical axis to plate surface. Channels are tilted to prevent incident particles from passing through the channels. The optimum angle is between 5° and 15° .

Open Area Ratio (OAR)

The OAR is the ratio of the open area to the total effective area of the MCP. For hexagonal arrays OAR=(p *O 3/6)*(d/P)2 where d is a channel diameter and P is a pitch (period of the hexagonal structure, or c-c distance). For 10-12 structure (d=10m m, P=12m m) OAR=63%, for 12-15 it's 58%, for 15-18 it's 63%. OAR limits ultimate detection sensitivity of MCPs. Particles incident on the MCP between channels are not detected. In many applications it is desired to make OAR as large as possible for more efficient input of primary electrons. For this purpose, there are custom MCPs in which the glass channel walls on the input side have been etched to increase the OAR up to 70 to 80%.

Metal Coating (Electrodes)

Over the input and output surfaces of a MCP, Inconel, Ni-Cr or Cr is evaporated to form electrodes. The thickness of the electrodes is controlled to have a surface resistance of 100 to 200W between the MCP edge. In general, the electrodes are evaporated to uniformly penetrate into the channels. The penetration depth significantly affects the angular and energy distributions of the output electrons, and usually chosen to be in the range of the channel diameter multiplied by 0.5 to 2. In such demanding applications as image intensification where spatial resolution is of prime importance, the penetration depth of the electrodes is controlled to be deeper in order to collimate the output electrons.

Gain

The gain of an MCP, g, is given by the following equation using the length-to-diameter ratio of the channel: g= exp (G*(L/d), where G is the secondary emission characteristics of the channel called gain factor. This gain factor is an inherent characteristic of the channel wall material and represented by a function of the electric field intensity inside the channel. Generally, L/D is designed to be around 40, which produces a gain of 104 with an applied voltage of 1 kV.

When an even higher gain is required, two or three MCPs are used to configure the two-stage or three-stage MCP assembly. These stacked MCP detectors can offer higher gains up to 108-109. Multiple-stage MCP gains are not the simple multiplication of the gain of each MCP because of the gain saturation caused by space charge effect near the output region of channels.

In these configurations the spatial resolution is degraded to some extent because a multiplying electron current spreads into several channels as it enters the latter-stage MCP. On the other hand the saturation level increases by a factor equal to the number of those spread channels.

Pulse height distribution

When a single particle create a single electron event in MCP, the output pulse height distribution shows normally an exponential function. However, in the region where the gain is saturated due to space charge effect, the pulse height distribution becomes peaked. This phenomenon is observed in the MCPs operating at a high gain, for instance, stacked MCPs.

Pulse height distribution is usually characterized by the ratio of the half-width at peak (full width at half maximum: FWHM) to the peak value in the pulse height distribution: FWHM/A; it is normally expressed in percentage. In general, is shows 120% or less for two-stage MCPs and 80% or less for three-stage MCPs.

Transit time

The transit time of MCP assemblies is very small. Due to the shorter electron transit distance compared to the discrete dynode used in the conventional PMT or SEM, transit time of the electron avalanche in MCP channels is in 100 ps range. The width of the single event peak determined mainly by temporal characteristics of readout device and electronics. Ultimate time resolution can be achieved using anode configuration matched with 50 W connector cable.

Spatial Resolution

Since each channel of the MCP serves as an independent electron multiplier, the channel diameter and center-to-center (c-c) spacing determine MCP resolution. Channel diameters ranging from 5 m m (6 m m c-c) to 15 m m (18 m m c-c) are standard.

When the output from MCP is observed with a phosphor screen, the spatial resolution also depends on the MCP electrode depth penetrating into the channels, the space between the MCP and the phosphor screen, and the accelerating voltage. Typical spatial resolution of a MCP composed of 10 m m diameter channels, which is observed with a phosphor screen, is about 40 l/mm. In the stacked MCP, the spatial resolution is less compared to that of a single MCP because it spreads into many channels as it enters the latter-stage MCP, and also because the increased gain makes greater the electrostatic repulsion in the space when the electrons are released from the MCP.

Dark Current

A typical MCP shows an exceptionally low dark current, less than 0.5pA/cm2 at an applied voltage of 1 kV. Even with a two or three-stage MCP, the dark count rate is low, less than 3 cps/cm2 at an applied voltage of 1 kV per stage.

Resistance

Glass composition and reduction processing conditions (time and temperature) can control the MCP resistance. Considering the output saturation, a lower resistance is desirable; however, there is a limitation in lowering the resistance as the MCP operating temperature rises due to higher power consumption.

MCP resistance is typically in the range between 100 and 1000 MW . For applications requiring high output currents, low-resistance MCPs of 20 to 30 MW are available.

Microchannel Plate Detectors with Single Metal Anode (MCP-MA)

|

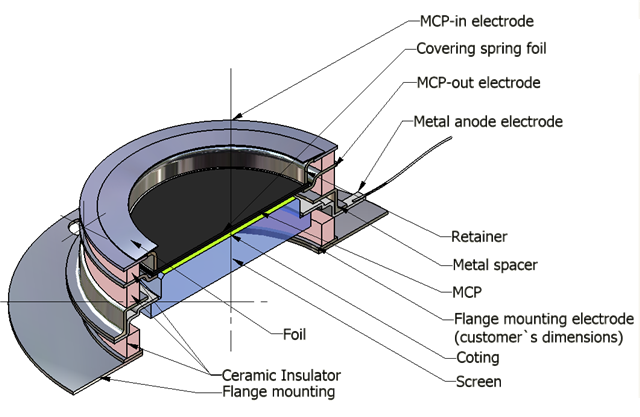

DEL MAR VENTURES Microchannel Plate Detectors MCP-MA series are an open MCP detectors with one or more microchannel plates and a single metal anode. They are intended for time-resolved detection and make use of high-speed response properties of the MCPs. MCP-MA detectors are used for photons and particles detection in vacuum chambers or in the space. |

|

The body of assembly is a metal-ceramic housing. Drawing shows two matched MCPs in V-stack (Chevron) assembly, which are fixed in place using retainer ring (above MCPs). Ceramic insulator rings are shown red. Detector is spot-welded to the support plate (available in different sizes). |

|

All parts of the assembly are highest quality components. Metal parts are polished to avoid electric discharges. Two MCPs are connected to each other via thin (40 -50 mm) copper or stainless steel foil ring. Direction of channel bias angle in the first MCP is opposite to one in the second MCP (chevron assembly). Typical voltages necessary for a gain of 104, resistances and dark current densities of Microchannel Plates are shown in the table below. Each detector is supplied with individual MCP data.

Specifications:

|

MCP-MA25 |

MCP-MA34 |

MCP-MA46 |

|

| MCP detector body |

metal-ceramic housing |

||

| Effective area diameter, min |

18mm |

25mm |

40mm |

| MCP type | 25-5, 24-10, 25-10 etc. |

33-10 or 34-10 |

46-12 |

| MCP Diameter, mm |

24.2 or 24.8 |

32.8 or 34 |

46 |

| MCP Thickness, mm |

0.46 |

0.46 |

0.5 |

| MCP channels pore-pitch, mm |

5-6, or 10-12 |

10 -12 |

12-15 |

| Typical Gain, (one MCP) |

104 - 104 |

||

|

(2 stack) |

106 - 107 |

||

|

(3 stack) |

108 - 109 |

||

| Time resolution |

< 1ns |

||

| PHD (2 stack assembly) |

FWHM/A<120% |

||

| PHD (3 stack assembly) |

FWHM/A<80% |

||

| Output |

Single metal anode |

||

| Strip current |

<20mA |

||

Operation conditions:

Wiring Methods

In general, MCP assemblies can be operated with any electrode (MCP-in, MCP-out or anode) at a ground potential.

When applying a voltage, do not apply the necessary voltage to the MCP at once. Slowly increase the applied voltage, with maximum 100 V step, until the optimum rating is reached, and verify if the MCP operates properly. In this procedure, also check the dark current by connecting an ammeter to the readout device. If there is an increase in the dark current, which might result from a small discharge, immediately turn off the applied voltage. After some time (depending on the situation) has passed, apply voltage to the MCP again in the same manner as described above. Note that the applied voltage to the MCP should be increased as slowly as possible even after normal operation has been verified.

Recommended and maximum applied voltage to MCPs and readout devices are as follows:

Set this voltage according to the required gain, 700 -1000V per MCP typical, 1100 V maximum, MCP out at positive polarity.

This is normally set at about 100 - 200 V.

A system pressure better than 6.5*10-4 Pa (5 *10-6 Torr) is necessary for proper operation. The MCP detector has to be degassed before applying the maximum voltage. Because the MCP is operated with a high voltage of about 1 kV per stage, a relatively high degree of vacuum must be required. If the MCP is operated at a deficient vacuum, not only will the noise increase due to the ion generation in the channels, but also the lifetime may be shortened. In the worst case, the MCP may be damaged by discharge. Therefore, it is recommended that the MCP be operated at a degree of vacuum as high as possible. When using a new MCP, it is recommended that before applying a voltage to it, the system be evacuated at a pressure of 6.5*10-4 Pa (5*10-6 Torr) or below for more than 24 hours. If the evacuation time is short or the degree of vacuum is deficient, a discharge may occur.

MCP Detector Mounting

MCP-MA34 detector can be mounted on the standard vacuum flange or on any other substrate. It can be either spot-welded or connected with screws. Figure below shows MCP-MA34 mounted on the standard 6" ConFlat Flange.

Open Microchannel Plate Imaging Detectors (MCP-GPS and MCP-IFP)

|

Open Microchannel Plate Imaging Detectors have a

design similar to MCP detectors with Metal Anode. Instead of simple metal

anode an aluminized phosphor screen is used as a readout device. An electron

cloud is drawn across a 0.7 mm gap by a high voltage onto micro-crystalline

phosphor screen where the kinetic energy of the electrons is released as

light. |

|

The phosphor screens deposited on a

glass window are realized in MCP-GPS series and on a fiber-optic plate in

MCP-IFP series. Drawing shows a cross-section of the imaging detector with a

fiber-optic plate.

The optical image can be viewed directly, or coupled to a camera. MCP-GPS and MCP-IFP imaging detectors are available in the same sizes and MCP-assembly options as MCP-MA detectors. Open imaging detectors must be operated in pressures of less than 6.5*10-4 Pa (5 *10-6 Torr). Recommended and maximum applied voltage to MCPs and phosphor screen are as follows:

Set this voltage according to the required gain, 700 -1000V per MCP typical, 1100 V maximum, MCP out at positive polarity.

A bias in the range 2.5-5 kV between MCP output and screen is required.

|

|

Microchannel Plate detectors optimized for imaging VUV and EUV

radiation

Next generation lithography research is one of the potential applications of the

new Microchannel Plate detectors optimized for imaging VUV and EUV radiation.

Current advanced lithographic equipment employs excimer lasers to produce

feature sizes at 180 nm. Extreme ultraviolet (EUV) lithography tools will use

13.5 nm light to image chips with feature sizes below 45 nm. Much development

work is still required in EUV radiation sources. Del Mar Ventures provide a

complete program of stationary and gated MCP- Detectors for the registration of

X-ray- and UV-radiation below 2000 Å. Each equipped with a single Au coated MCP

plate and a phosphor screen on a fiber optic plate, which also serves as a

vacuum to air interface. Devending on the detector model phosphor screen is

either uniform or sectioned in several independent sectors or stripes. In

multi-frame units, each individual sector or stripe can be gated separately with

a time resolusion as short as 3 ns. This allows to obtain images or spectra or

both at individual times. Gated MCP detectors supplied with optional high

voltage pulse generator that provides four high voltage outputs with variable

delay time and width. Versatile trigger options, including an internal delay

generator allow for an easy adaptation to the experimental requirements.

Microchannel Plate Detectors MCP-MA

DEL MAR Microchannel Plate Detectors MCP-MA series are an open MCP detectors

with one or more microchannel plates and a single metal anode. They are intended

for time-resolved detection and make use of high-speed response properties of

the MCPs. MCP-MA detectors are designed for photons and particles detection in

vacuum chambers or in the space.

MCP-MA detectors are used in a variety of applications including UV, VUV and EUV

spectroscopy, atomic and molecular physics, TOF mass–spectrometry of clusters

and biomolecules, surface studies and space research.

MCP-MA detectors supplied as a totally assembled unit that can be easily mounted

on any support substrate or directly on a vacuum flange. They also can be

supplied premounted on a standard ConFlat flanges.

| Model | Product Name+ | Price | Buy Now |

| MCP 25-10E | Microchannel Plate MCP 25-10E | $320.00 |

|

| MCP 33-10E | Microchannel Plate MCP 33-10E | $350.00 |

|

| MCP 34-10 | Microchannel Plate MCP 34-10 | $350.00 |

|

| MCP 43-63 | Microchannel Plate MCP 43x63 | $1,990.00 |

|

| MCP 46-12 | Microchannel Plate MCP 46-12 | $990.00 |

|

| MCP 56-15 | Microchannel Plate MCP 56-15 | $1,590.00 |

|

| MCP 70-90 | Microchannel Plate MCP 70x90 | $3,690.00 |

|

| Displaying 1 to 7 (of 7 products) |

![]()

| Model | Product Name+ | Price | Buy Now |

| MCP 34/2 G | Microchannel plate detector MCP 34/2 G | $1,200.00 |

|

| MCP-MA 25/2 | Microchannel plate detector MCP-MA 25/2 | $1,490.00 |

|

| MCP-MA 25/2 SP37 | Microchannel plate detector MCP-MA 25/2 | $1,490.00 |

|

| MCP-MA 25/2 SP70 | Microchannel plate detector MCP-MA 25/2 | $1,490.00 |

|

| MCP-GPS 34/2 | Microchannel plate imaging detector MCP-GPS 34/2 | $2,600.00 |

|

| MCP-IFP 25/2 | Microchannel plate imaging detector MCP-IFP 25/2 | $2,190.00 |

|

| MCP-IFP 34/2 | Microchannel plate imaging detector MCP-IFP 34/2 | $2,800.00 |

|

| Displaying 1 to 7 (of 7 products) |